Industrial and urban symbiosis in Bro

Biogas on Gotland is utilized in a circular collaboration.

Advantages

- Circular economy

- Fossil-free energy

- Waste and by-products

Overview

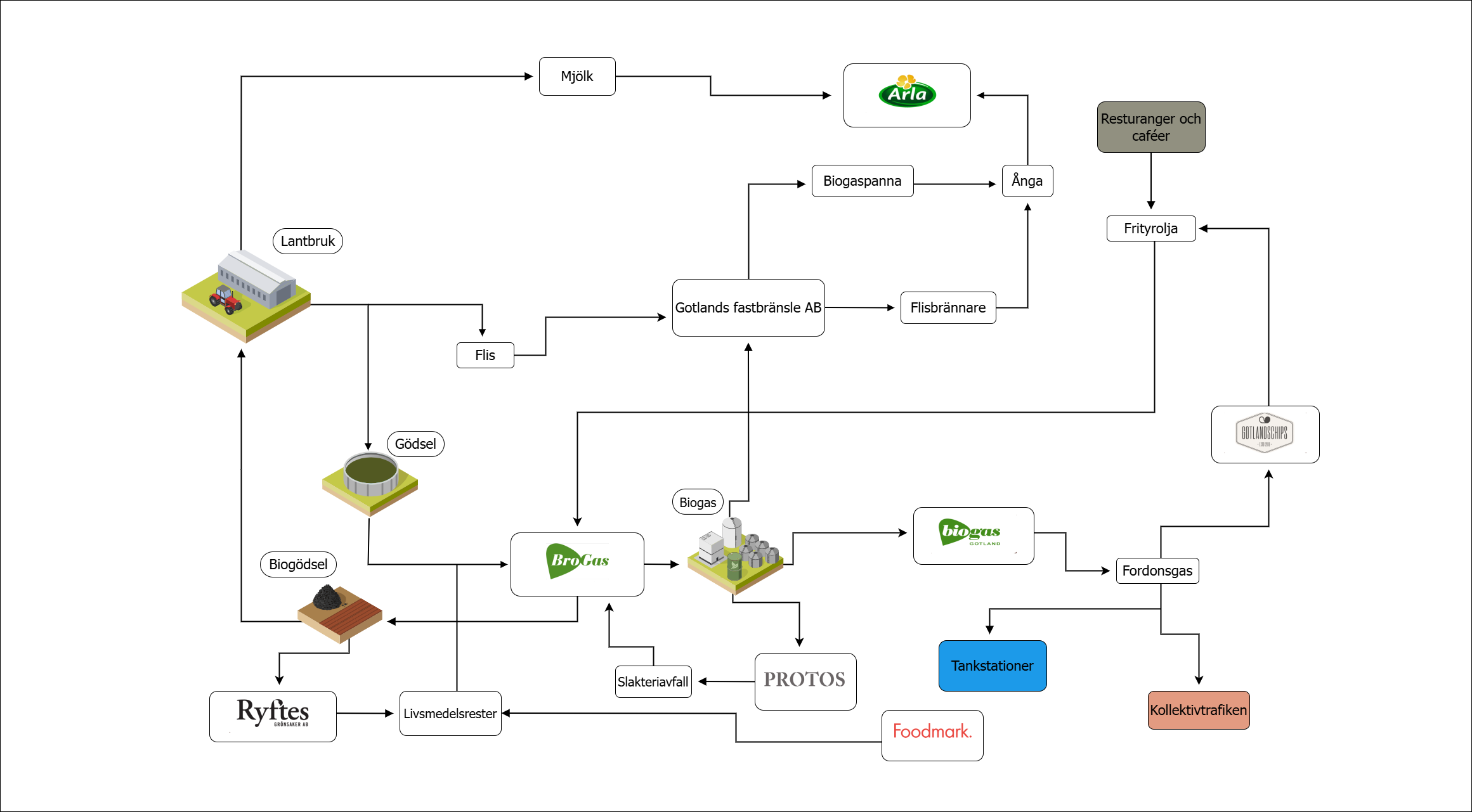

BroGas' biogas plant on Gotland produces about 40 GWh of biogas per year (equivalent to approximately 4 million liters of gasoline). Biogas is produced through anaerobic digestion. The gas consists of about 60 percent methane and 40 percent carbon dioxide, with a small amount of sulfur compounds. There are currently two upgrading plants on the island (Lundbygatan and Färjeleden in Visby) and four biogas refueling stations with vehicle-grade gas—two in Visby and one in the north and one in Sudret. The Bro plant produces biogas using about 130,000 tons of substrate (raw materials for the process) sourced from the island’s waste and by-products, such as liquid and solid manure, slaughterhouse waste, food waste, discarded root vegetables, grain screenings, discarded silage, and collected frying oil from the island's many restaurants and cafes.

A fantastic and circular aspect of the biogas production is that from the 130,000 tons of incoming substrate, not only is high-quality fuel equivalent to about 4 million liters of gasoline extracted, but almost as many tons of biogas slurry (around 125,000 tons) are returned as biogas fertilizer.

Highlights

Thanks to collaborations with several farmers, over 90,000 tons of Bro facility’s substrate comes from the island's livestock farms. BroGas collects manure and returns an equal or greater amount of biogas slurry. Biogas from the Bro facility is transported via a pipeline to Visby, where it is either used for producing process steam and heat by Protos, or through Gotlands Fastbränsle AB to Arla, or upgraded to vehicle-grade gas (about 97 percent methane) by Biogas Gotland, which then delivers the upgraded biogas to the vehicle gas market and also to Gotland Chips.

Driving forces and enablers

The demand for vehicle gas is steadily increasing. At the same time, Arla has long had the goal of converting its Visby dairy into a completely fossil-free production. To support Arla in achieving its goal, while also gradually freeing up the majority of the biogas previously supplied to Arla for the expanding vehicle gas market, Gotlands Fastbränsle has also built a wood chip plant. Since mid-February 2021, this facility has supplied Arla with the entire dairy's need for fossil-free process steam and heat (about 35 GWh, equivalent to 3.5 million liters of heating oil).

Thus, the Visby facility is Arla Group's first completely fossil-free dairy for milk powder production. Thanks to this investment, the biogas previously supplied to Arla (about 16 GWh, equivalent to around 1.6 million liters of gasoline) can gradually be redirected to the island’s vehicles as demand for fossil-free fuels increases.