Industrial and urban symbiosis in Hofors

Waste heat from the steel industry heats the community in Hofors.

Advantages

- Efficiency and sustainability

- Economic values

- Environmental impact and emissions

Overview

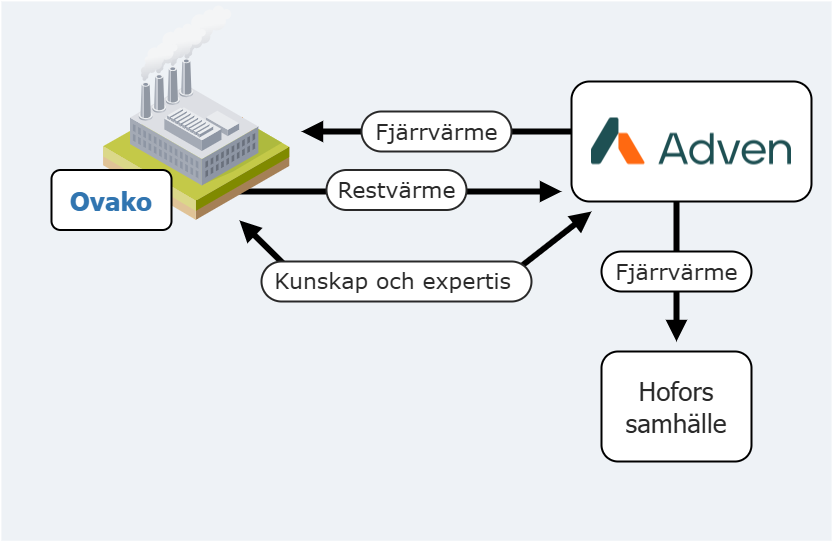

In the small community of Hofors, an industrial symbiosis between the steel industry and a district heating operator has been growing stronger every year. The collaboration between Adven and Ovako began as early as 2002, where there was an unused opportunity to harness the waste heat from Ovako's steel production. Large amounts of heat from cooling water and hot exhaust gases from several furnaces could be reused to heat the community instead of being released into the air. The partnership has made it possible for up to 40% of the heat distributed throughout Hofors to come from Ovako's steel production.

Highlights

The industrial symbiosis in Hofors has also contributed to the development of new ways to utilize waste resources. When Ovako in Hofors became the first to heat steel with fossil-free hydrogen from its electrolysis plant, Adven helped ensure that the solution was also adapted to capture waste heat. By integrating the plant with the district heating network from the start, the excess heat could be recovered despite the technical challenges the project involved.

- Waste heat is not free, but there are enormous values to be saved for the benefit of the climate, both for the industry and the community, says Lars Sjökvist, waste heat expert at Adven.

The collaboration with the electrolysis plant is expected to contribute an additional 3–9 GWh of waste heat per year. By jointly developing the symbiosis, Adven and Ovako have increased risk diversification for the district heating network and created a sustainable and innovative steel industry.

Driving forces and enablers

The long-standing partnership between Adven and Ovako has created a close and effective collaboration, both geographically and technically. Since the district heating plant is located on Ovako's industrial site in Hofors, there are excellent conditions for working together smoothly. Additionally, the work method where the companies have combined their expertise has been one of the driving forces behind new ideas, including the technology used in the construction of the electrolysis plant.